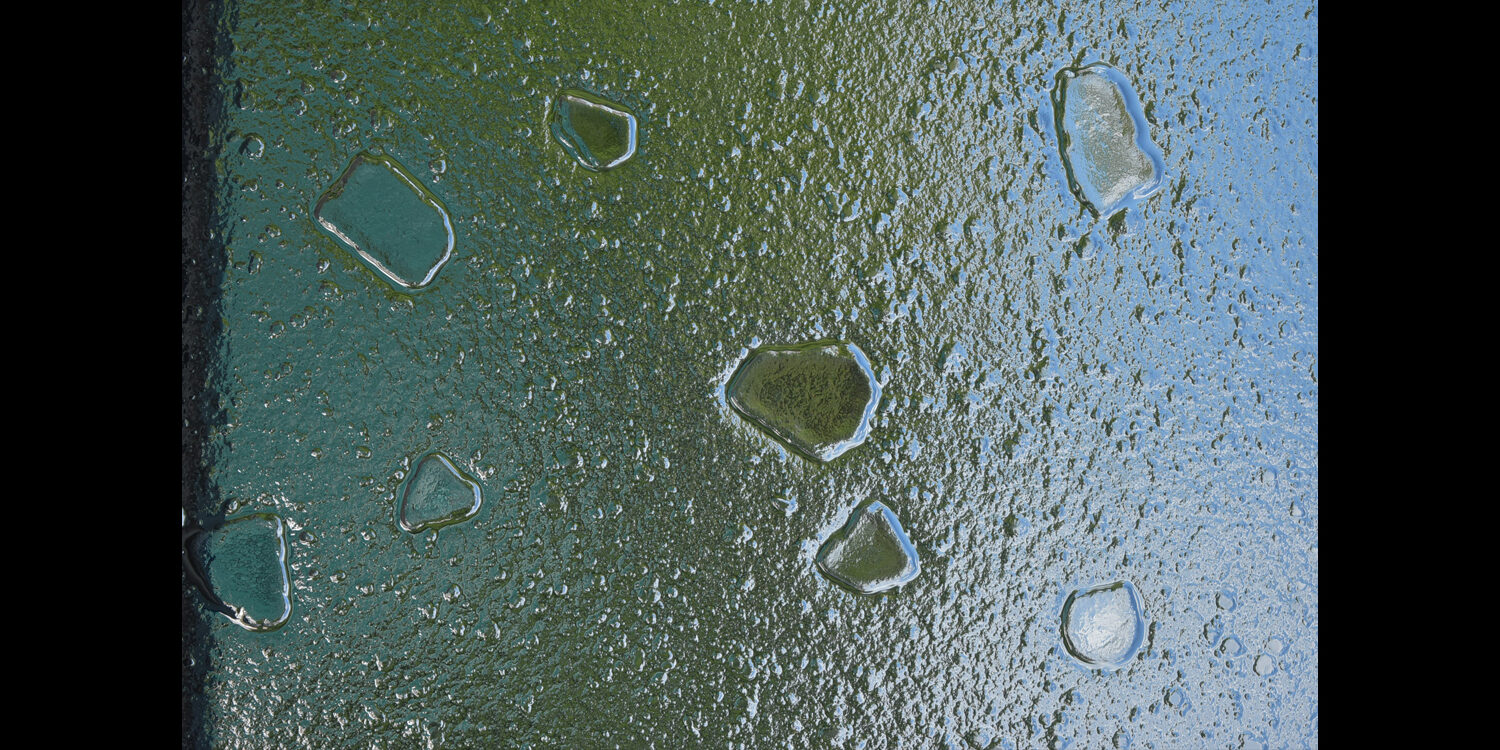

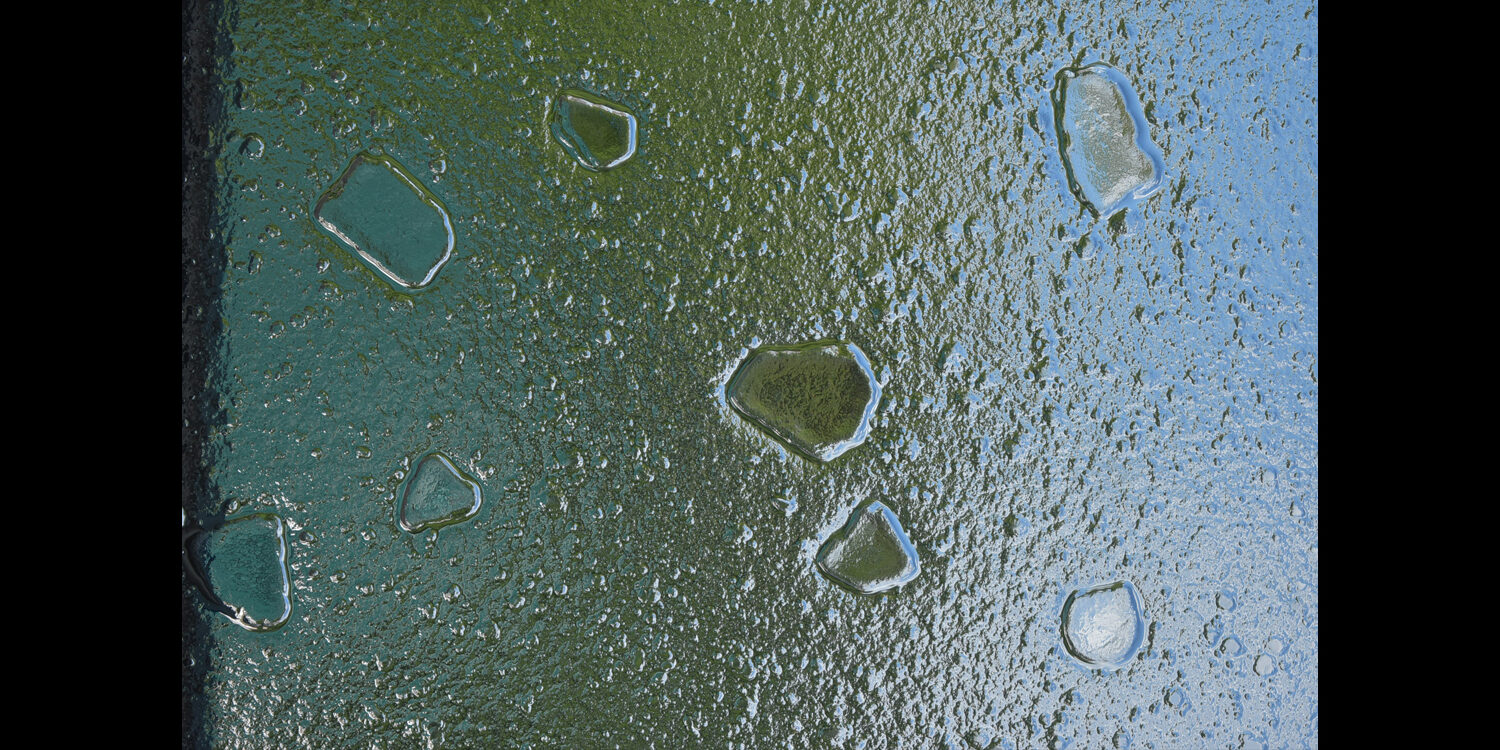

Properties & Qualities

Application

Architecture Art Sample making

Qualities

2D 3D Transparent

Colour

Other

Sample Information

Date of creation

July 10th, 2023

Dimensions

21cm x 30cm x 0.6cm

Weight

0.94 kg

Process & Production

| Cutting special ceramic fible templates to the desired shape. Putting ceramic fible templates onto the kilnshelf. Laying a sheet of glass onto the templates and firing at around 800° C. The glass will slump around the templates, creating relief effects and textures. Cutting special compatible kiln glass, in this case clear glass, to the desired shape.assembling the cut pieces with the slumped glass on the kilnshelf. Firing in the kiln at lower temperatures than a full fuse. The glass will stick together to form a single piece where every glass component still retains all or most of its individual characteristics. |

Credits

Craft Maker

Glasmalerei Peters Studios

Photographer

Glasmalerei Peters Studios