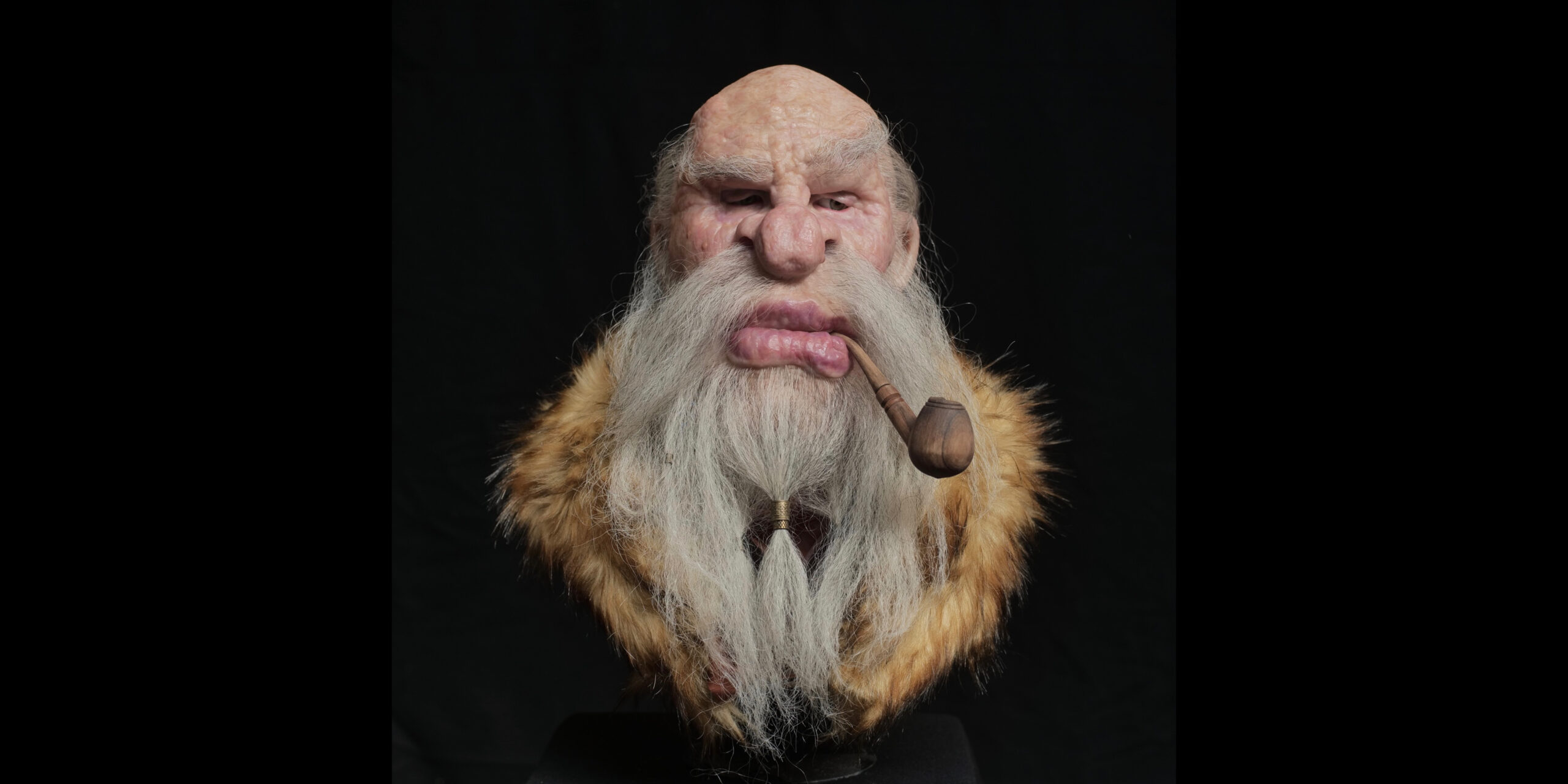

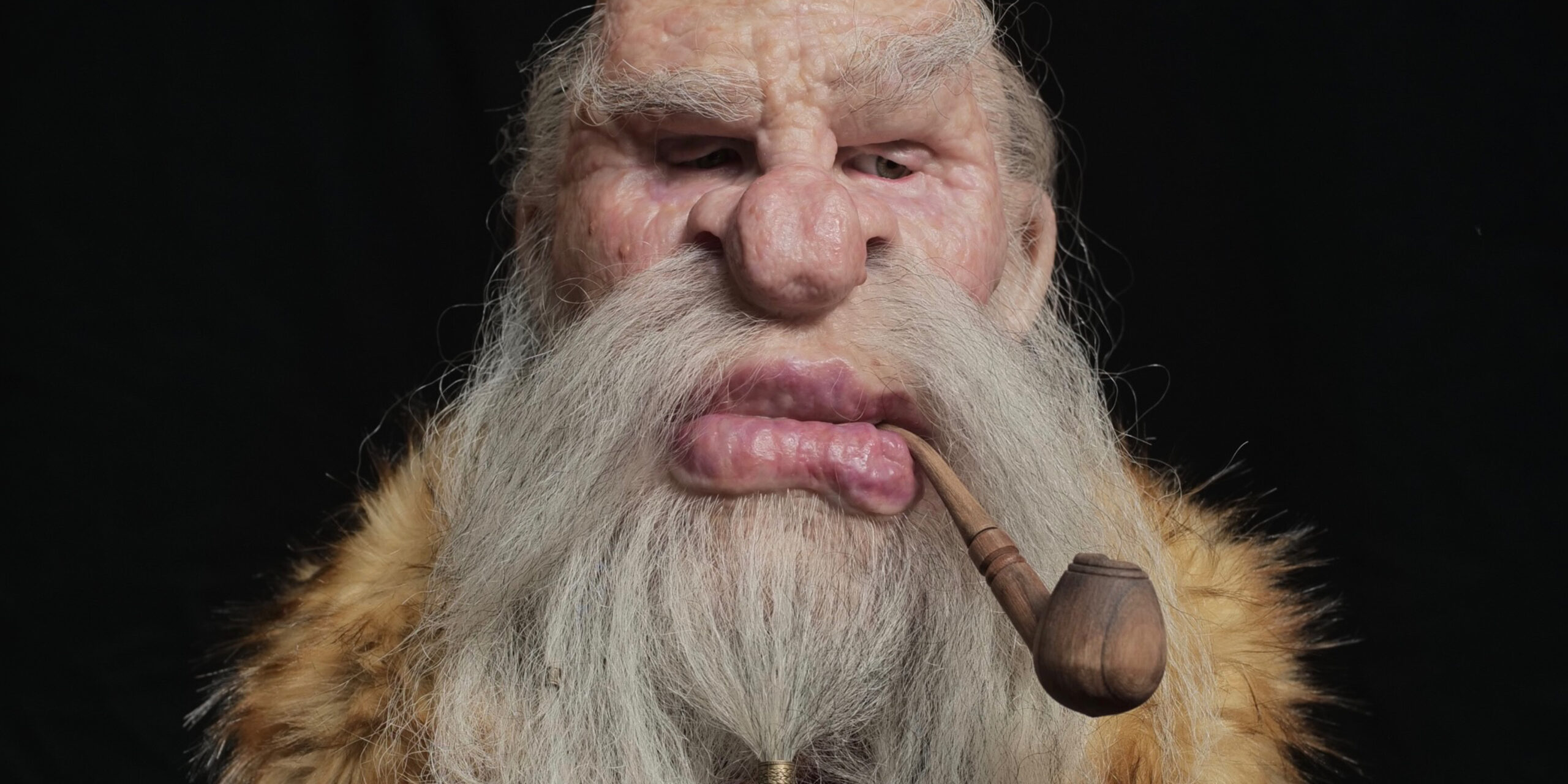

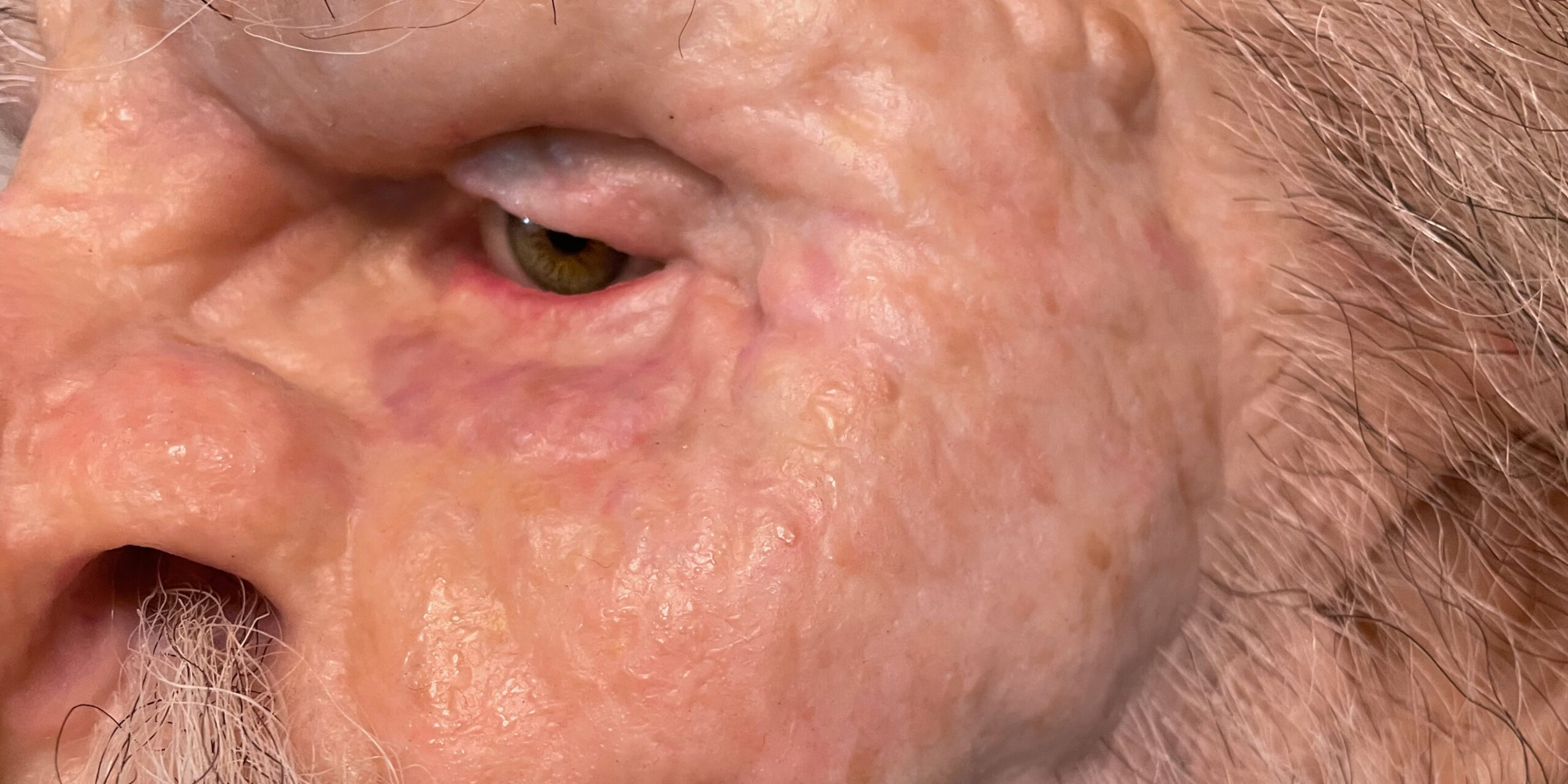

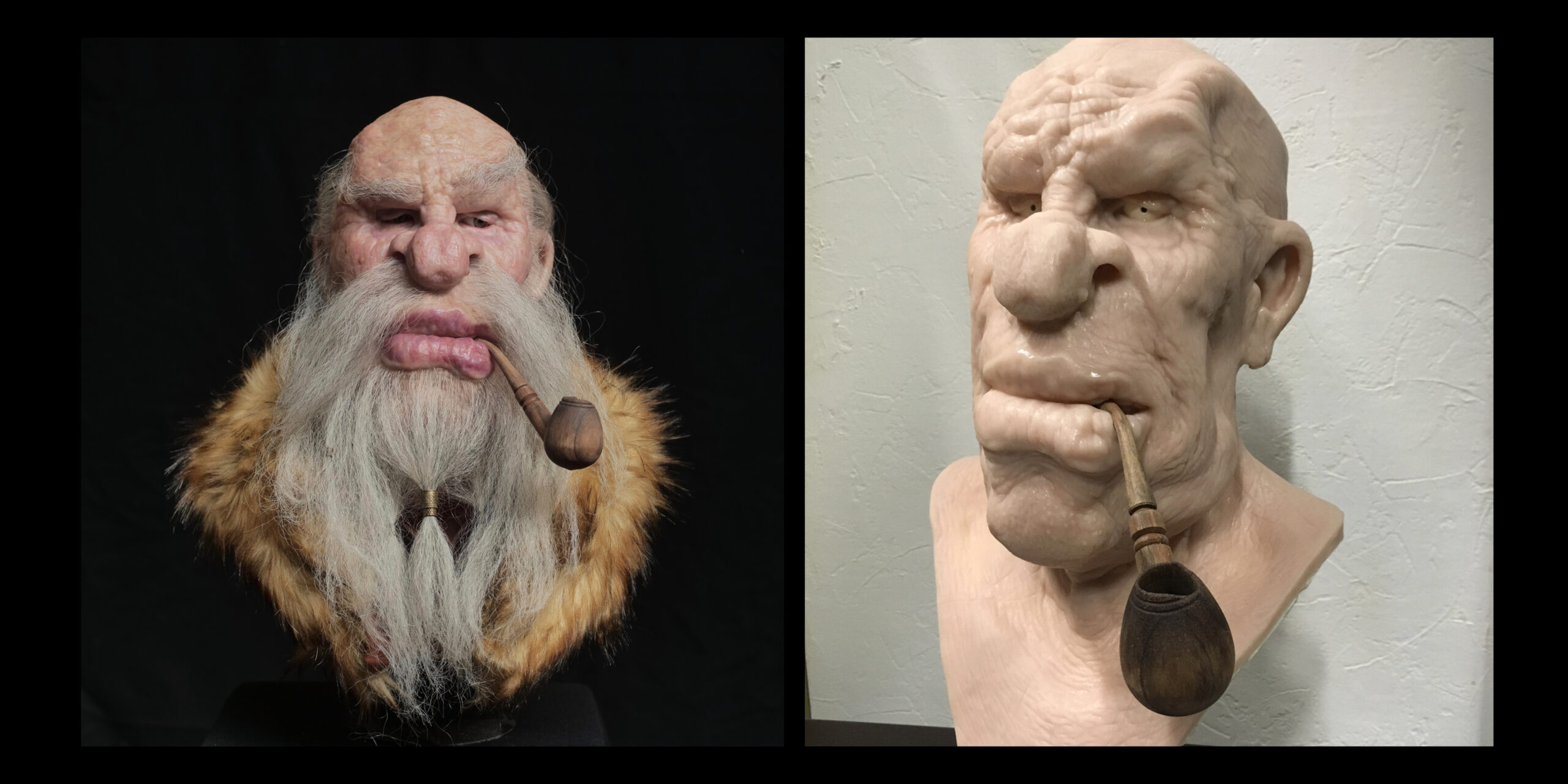

Properties & Qualities

Application

Sculpture Other

Colour

Transparent viscus liquid. It can be dyed and painted

Sample Information

Date of creation

2010

Weight

It comes in kit from 500g – 40kg

Culture & Context

This material has be used to create many of the characters and creatures we see on screen today.

Process & Production

PlatSil Gel 25 is a Shore A25 hardness, 1A:1B mix ratio, liquid platinum silicone rubber with a 5 minute pour time and a 1 hour demould time. Use PlatSil Gel 25 as a mould rubber, to create prosthetic appliances and for life casting. PlatSil Gels are widely used for specials effects in television, theatre and film. Gel 25 has a lower mixed viscosity than other PlatSil Gels and is very versatile when used in conjunction with PlatSil accessories.

“Deaden” the rubber to soften and eliminate the snappy, synthetic look and feel of ordinary silicone rubbers. Deadened Gel 25 can be made to look, feel and move like all types of living tissue. Unlike silicone fluid, Smith’s Theatrical Prosthetic Deadener & PlatSil Deadener LV do not leach from the cured rubber/appliance so bonding and use are far easier. Use PlatSil Part H Hardener to increase the Shore hardness. Using these two accessories, Gel 25 can be made as soft as Shore OOO30 and as hard as Shore A40. Accessories are also available to increase working time; accelerate cure time; thicken the mix for brushing/layering; thin the mix for easier pouring or for softening.

Recipe Details

Plat Sil 25 Formulas

Ratios:

1A: 1B: 1H Demold time = 2 hour. Hardner Shore Hardness A40 (Teeth Mould)

1A: 1B: 0D Demold time = 1 hour. Shore Hardness A25 (Flat Plate Mould)

1A: 1B: 0.25D Demold time = 0.5 hour. Shore Hardness A15

1A: 1B: 0.5D Demold time = 0.5 hour. Shore Hardness A10

1A: 1B: 1D Demold time = 0.5 hour. Shore Hardness 0025 (Firm Appliance)

1A: 1B: 1.5D Demold time = 0.5 hour. Shore Hardness 0028 (Medium Appliance)

1A: 1B: 2D Demold time = 0.5 hour. Shore Hardness 00035 (Soft Appliance)

Max Deadner is 6D Demold time = 1 hour. (Extremley Soft)

Percentages:

50%A + 50%B + 50%H Demold time = 1 hour. Hardner Shore Hardness A40 (Teeth Mould)

50%A + 50%B + 0%D Demold time = 1 hour. Shore Hardness A25 (Flat Plate Mould)

50%A + 50%B + 12%D Demold time = 0.5 hour. Shore Hardness A15

50%A + 50%B + 25%D Demold time = 0.5 hour. Shore Hardness A10

50%A + 50%B + 50%D Demold time = 0.5 hour. Shore Hardness 0025 (Firm Appliance)

50%A + 50%B + 75%D Demold time = 0.5 hour. Shore Hardness 0028 (Medium Appliance)

50%A + 50%B + 100%D Demold time = 0.5 hour. Shore Hardness 00035 (Soft Appliance)

Max Deadner is 300% Demold time = 1 hour. (Extremley Soft)

Credits

Craft Maker

Paul McJulia Donnell

Library Contributor

National College of Art & Design Ireland

Photographer

Paul McDonnell