Properties & Qualities

Application

Art Sample Making Product

Qualities

Translucent

Colour

Other - Glass

Sample Information

Date of creation

2021

Dimensions

Individual drinking glasses: 80mm x 10mm x 60mm Decanter: 300mm x 150mm x 100mm

Weight

Individual drinking glasses: 200g Decanter: 900g

Culture & Context

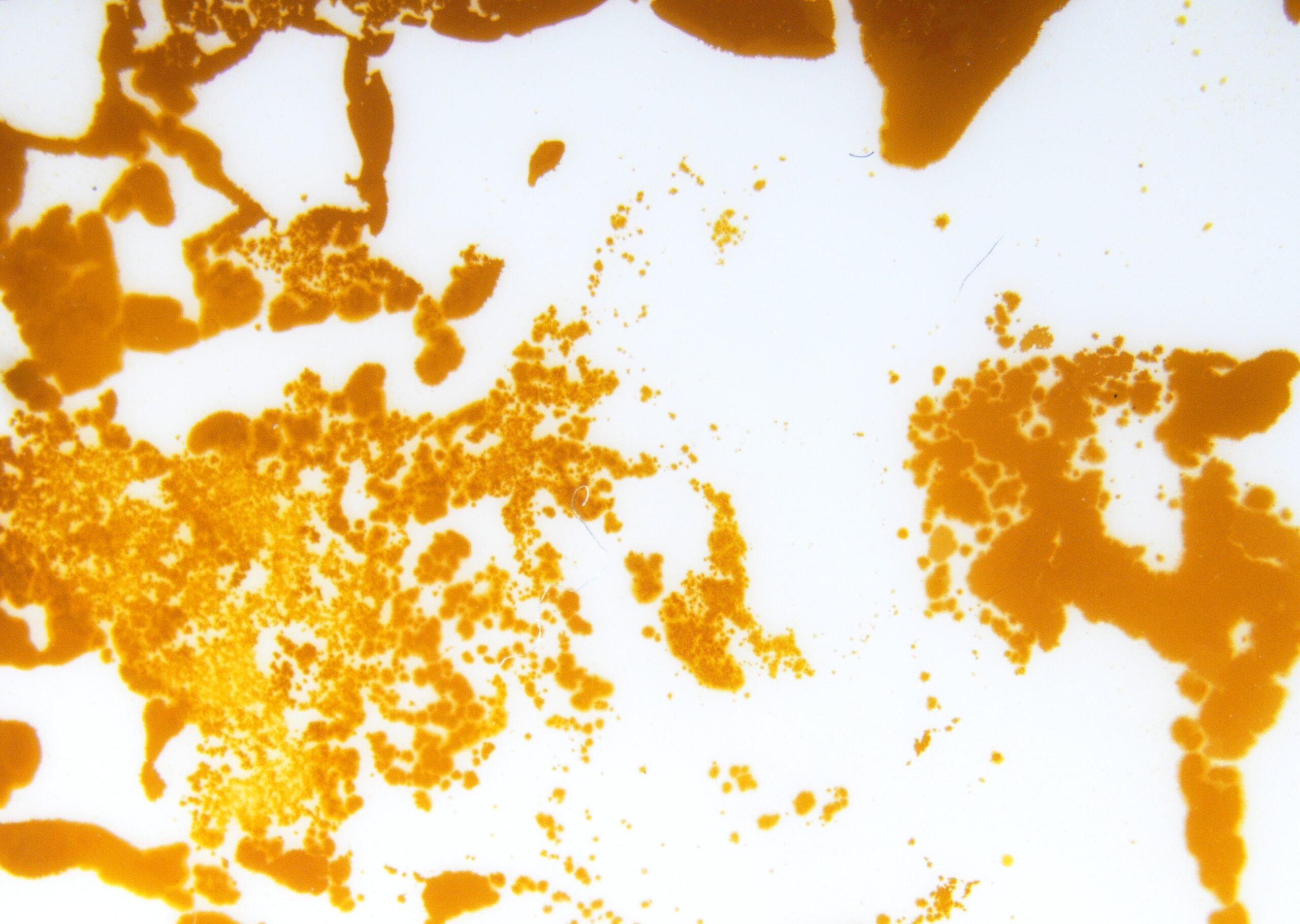

The Eorna Whiskey Decanter and Glasses were created especially for an exhibition in the Lavit Gallery in Cork called Lúnasa, curated by Stephen O’ Connell. Lúnasa is the Irish word for August, and celebrates the harvest festival. The form of the glass was inspired by the barley grain, harvested each year to create whiskey. I created the form on CAD, and 3D printed it before casting a blow mould around the printed form.

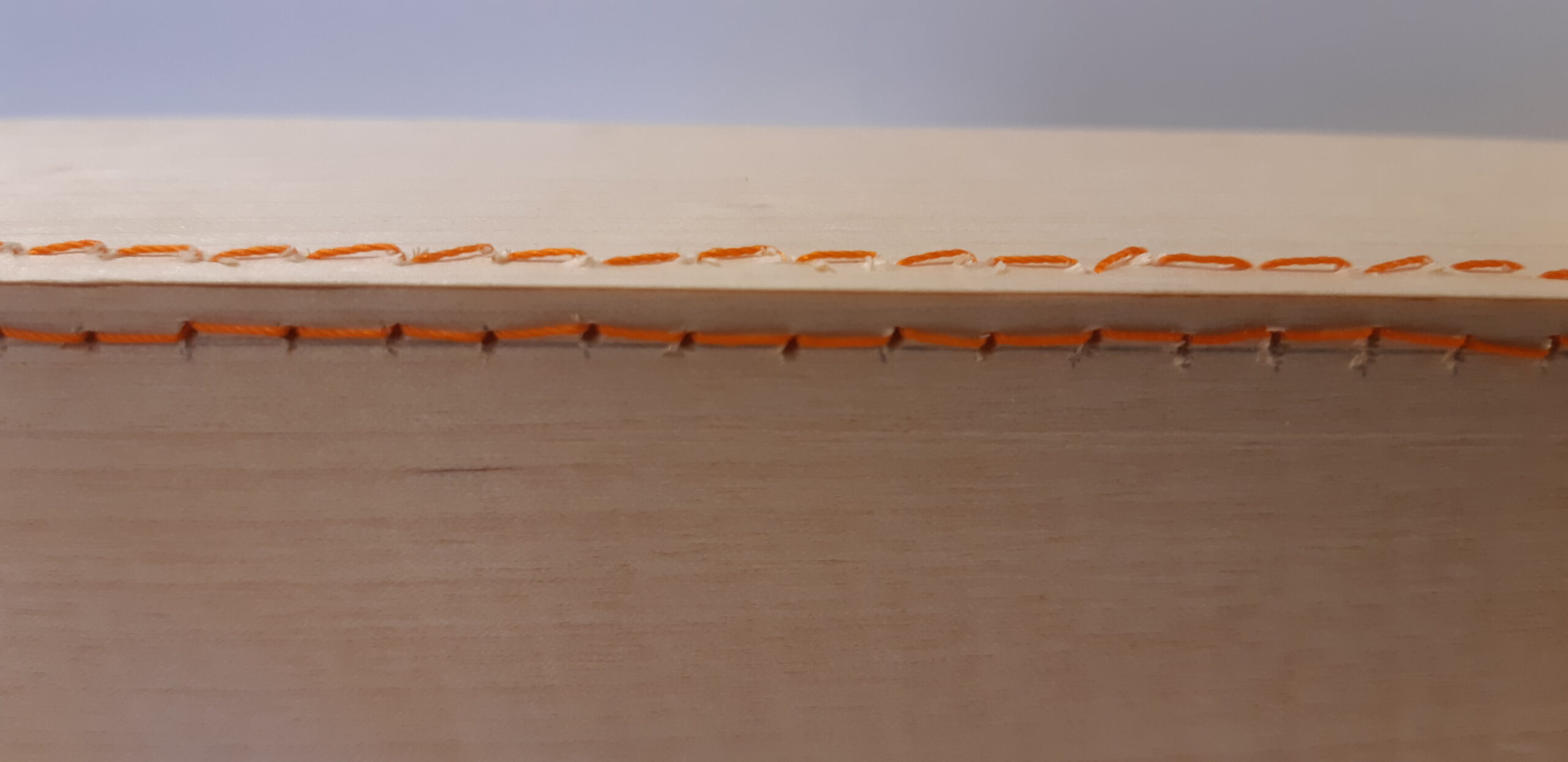

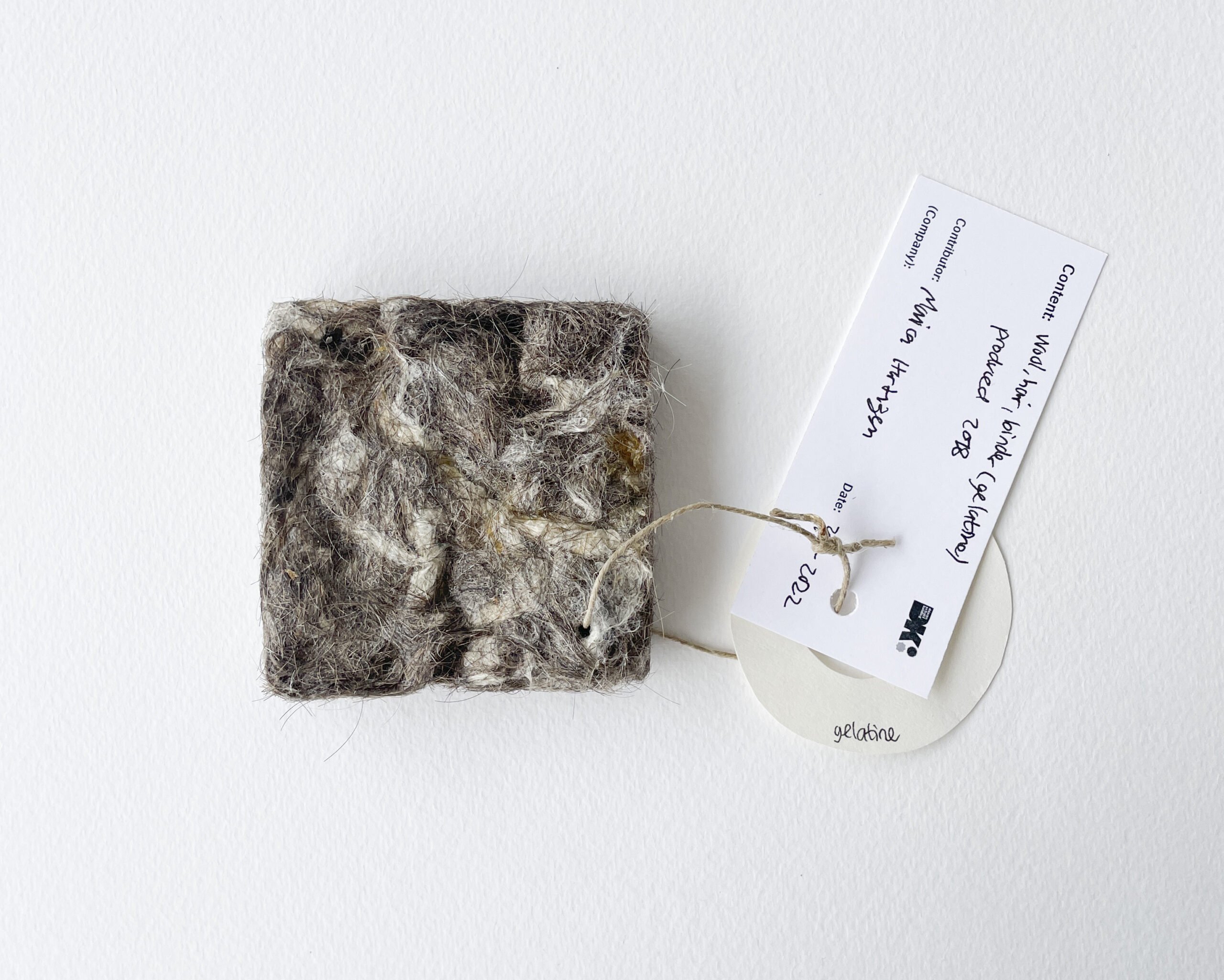

Normally I create my glass blowing mould mixture using plaster, sawdust and toilet paper pulp (see link to video tutorial), this allows the mould to remain damp when blowing into it, and prevent cracking. This time I used local soil mixed with the plaster to keep it damp. The molten glass is gathered and shaped before being blown into the mould, the final shape is then harvested from the mould, just as the barley is harvested from the soil.

Recipe Details

Credits

Craft Maker

Laura Quinn

Library Contributor

National College of Art & Design Ireland

Photographer

Laura Quinn