Properties & Qualities

Application

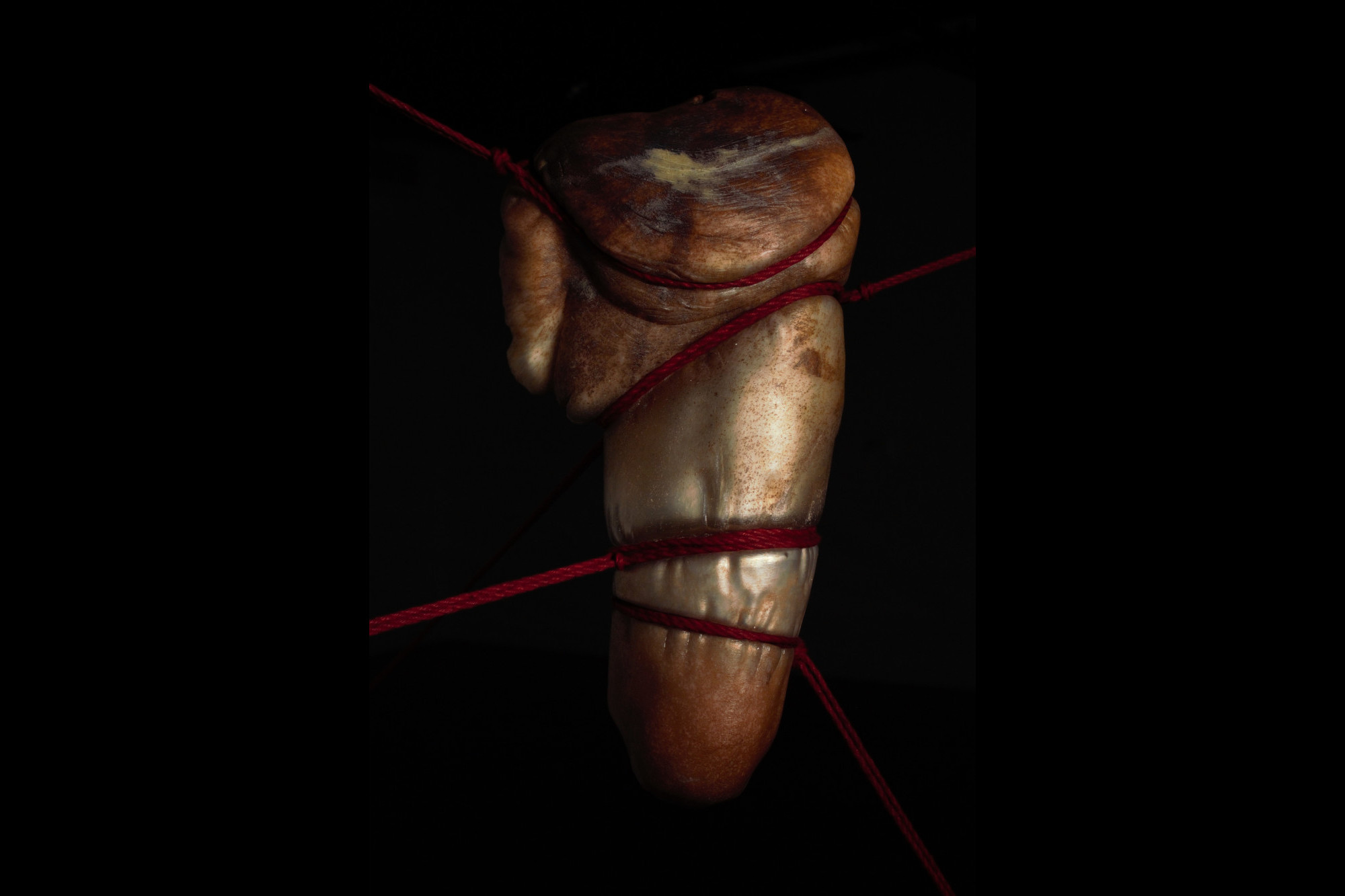

Sculpture

Colour

Yellow Pink Brown Other

Sample Information

Date of creation

March, 2023

Dimensions

H 53cm x W 33cm x D 28cm

Culture & Context

Similar to the lost-wax casting technique, these blow moulds begin with a wax positive that will be invested in refractory material (plaster/silica) and steamed out, leaving a negative space within the mold.

When the mold has dried, it can be placed in a kiln and brought, slowly, up to 550 Celsius. Once up to temperature, the mold can be blown into, whereby annealing the mold and the glass together. After annealing, the mold can be broken open and the glass cold-worked.

Working large scale, it is difficult to get colour directly on the outside of the glass (which is important to achieve likeliness to skin). To overcome this, a large “stuff cup” is made using solid, bar colour as a base and a mix of powders on the final gather.

Recipe Details

Mold-mix: 50/50 plaster/silica, reinforced with woven fiber glass on the 3rd and 4th layers.

Colour application: layering multiple glass colours while hot by rolling fresh gathers into glass powders

Credits

Craft Maker

Sadhbh Mowlds

Library Contributor

National College of Art & Design Ireland

Photographer

Sadhbh Mowlds